Last updated on July 6th, 2024 at 11:18 pm

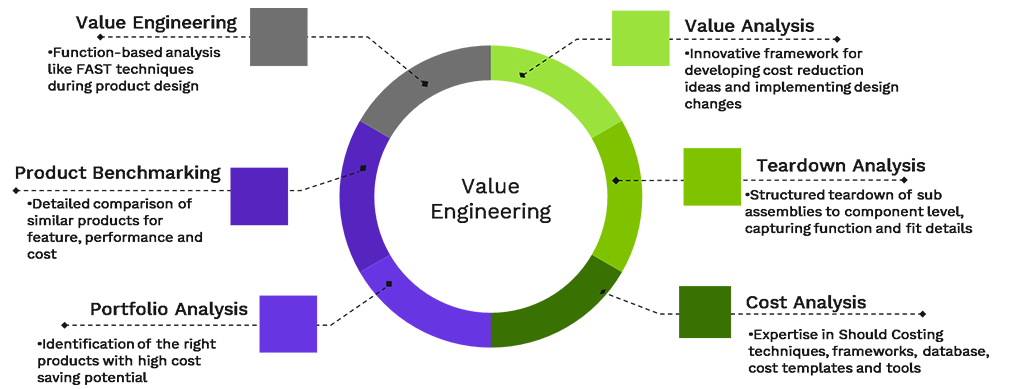

Value engineering meaning is a systematic method used to improve the value of a product or service by reducing its cost and increasing its functionality. It is a way to increase the overall value of a product or service while also reducing costs.

What is Value Engineering?

Value engineering is a systematic, organized approach to improving the value of a product that a project produces. Value engineering is used to analyse a service, system, or product to determine the best way to manage important functions while reducing the cost. This encourages the use of alternate methods and materials that are less expensive and do not lower the functionality of the system, service, or product. Value engineering takes place after the completion of the design process, but it is best performed before the design is conducted to allow the experts to incorporate the option of using alternative materials and methods. Most of the engineering projects opt for a team approach, where subject matter experts work together to execute the value methodology.

History of Value Engineering

Value engineering is the review of new or existing products during the design phase to reduce costs and increase functionality. This increases the value of the product. The value of an item is defined as the most cost-effective way of producing an item. Therefore, reducing costs at the expense of quality is simply a cost-cutting strategy. The concept of Value Engineering was first introduced in the 1940s at General Electric, in the midst of World War II. As there was a shortage of components during the war, engineer Lawrence Miles and others sought substitute materials. These substitutes were often found to reduce costs and provide equal or better performance.

The Systematic Approach of Value Engineering

Value engineering is a systematic approach that aims to improve the value of a product or service. This involves detailed analysis and the use of alternative methods and materials that can lead to significant cost reductions and improved performance. The process begins with a thorough understanding of the project’s objectives and the identification of areas where improvements can be made. By employing a structured methodology, value engineering ensures that the most cost-effective solutions are implemented without compromising on the quality or functionality of the product or service. This approach is particularly beneficial in long-term projects, where the cumulative savings and enhancements can lead to substantial value over the entire life cycle of the product or service.

Steps in Value Engineering

Value engineering can be broken down into the following steps:

- Information

The information phase involves gathering project information and refining the goals of the project. Data is collected and analysed, and the information obtained is used to finalize the priorities of the project and areas of improvement.

- Function Analysis

The function analysis phase involves determining the functions of the project and identifying them with a verb/noun combination for every element under evaluation. The function is defined as the set of targets to be attained through the execution of an element or a set of elements.

- Creative

This phase involves exploring various ways to perform the function(s). This allows team members to brainstorm alternatives to existing systems or methods that are in use.

- Evaluation

The merits and demerits of each solution and alternatives are listed during the evaluation phase. The team should be able to describe each advantage and disadvantage in general terms.

- Development

An in-depth analysis is conducted during the development phase. Implementation cost analysis is also involved. The examination of each alternative may involve creating sketches, cost estimates, and other technical analyses.

- Presentation

During the presentation phase, the team meets with the management and other stakeholders to present their final report. The team is required to present their findings to the decision-makers using reports, flow charts, and other presentation materials to convince them that the final ideas from the development phase should be implemented.

- Implementation

Implementation of the project begins after the management’s approval of the team recommendations. If there are changes requested by the management or other decision-makers, these changes should be incorporated into the implementation plan before the implementation begins.

Examples

Value engineering can be applied to a wide range of products and services, and there are many examples of how it has been used to improve the value and reduce costs. Here are a few examples:

- Manufacturing: A manufacturing company was producing a complex piece of machinery that was not meeting customer expectations in terms of performance and reliability. A value engineering team was assembled to analyze the design, materials, and manufacturing processes used to create the machinery. The team identified several areas for improvement, such as redesigning certain components to be more durable and using a different manufacturing process to improve the product’s performance. These changes resulted in a more reliable and functional product, which led to increased customer satisfaction and reduced costs.

- Construction: A construction company was building a large commercial building and was facing cost overruns due to the high cost of materials and labor. A value engineering team was assembled to analyze the design and construction processes used to build the building. The team identified several areas for improvement, such as using alternative materials that were less expensive and modifying the design to reduce the amount of labor required. These changes resulted in a cost savings of more than 15%.

- Automotive: An automotive company was producing a car model that was not selling well due to its high cost. A value engineering team was assembled to analyze the design, materials, and manufacturing processes used to create the car. The team identified several areas for improvement, such as using alternative materials that were less expensive and redesigning certain components to reduce the cost of manufacturing. These changes resulted in a cost savings of more than 20% and an increase in sales.

- Business processes: A large retail company was facing issues with its logistics and inventory management. A value engineering team was assembled to analyze the company’s logistics and inventory management processes. The team identified several areas for improvement, such as implementing automated inventory management systems and redesigning the logistics process to reduce the number of intermediaries. These changes resulted in improved inventory management, lower costs and an increase in customer satisfaction

These are just a few examples of how value engineering has been used to improve the value and reduce costs in different industries. The key is to identify the problem or opportunity, assemble a team of experts, and use a structured process to analyze and develop solutions.